SOLIDWORKS PCB

SOLIDWORKS® PCB — powered by Altium®— is a mechatronics/electronics design solution that provides the best in PCB design technology with an integrated electro-mechanical collaboration solution.

Why Choose SOLIDWORKS PCB?

SOLIDWORKS PCB enables the productivity you need to design Printed Circuit Boards (PCBs) quickly along with unique, collaboration between electrical and 3D mechanical design teams. It offers a clear advantage where ECAD-MCAD collaboration is critical for overall success of electronic product design.

Rigid-Flex Design

Define rigid-flex regions, layers, and stack thicknesses enabling single board rigid-flex PCB design. The rigid-flex layer stack regions can be defined with bend lines and angles and validated with 3D folding and component clearance checking to ensure layout correctness.

Design and Data Management

Manage project, design files and documentation with SOLIDWORKS PCB-PDM Connector and the SOLIDWORKS PDM-based design and data management workflow. Securely store and index design data for fast retrieval, eliminate concerns over version control and data loss, and collaborate on design data from multiple locations.

ECAD-MCAD Design Collaboration

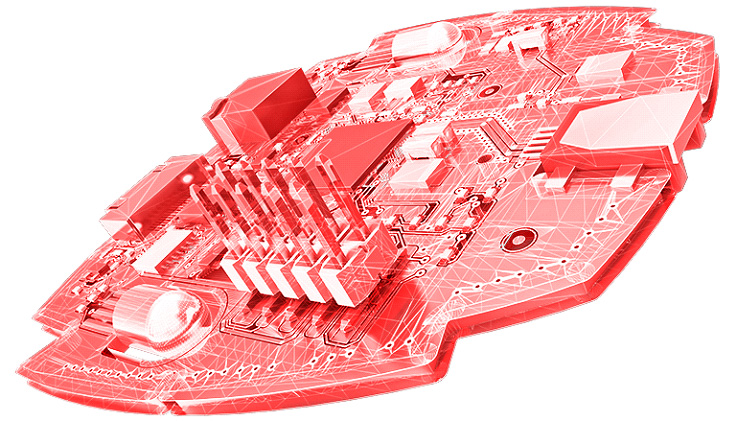

Unmatched ECAD-MCAD integration and collaboration with SOLIDWORKS that unifies design data and pushes changes to both sides of the design project.

PCB Design Engine

Industry-proven, Altium-based design engine for layout and routing of printed circuit boards.

Modern Schematic Entry

Full-featured Altium-based schematic capture tool with extensive drafting capabilities, libraries, and electrical rules.

Streamlined Interface

Intuitive and easy-to-use interface–inspired by SOLIDWORKS–with a consistent editor and use-model between schematic capture and board layout.

Managed ECAD-MCAD ECO Process

A managed Engineering Change Order (ECO) process to and from SOLIDWORKS PCB and SOLIDWORKS 3D CAD takes care of design changes including board shape, component placement, mounting holes, and cutouts, which keeps designs in sync.

Real-time 3D Clearance Checking

Visualize the PCB with components inside of the mechanical enclosure to reduce costly prototypes by ensuring that the board and components fit the mechanical enclosures with real-time 3D clearance checking.

Mixed-Mode SPICE 3f5 Simulator

Simulate and analyze analog and mixed-signal circuits from within the schematic editor to make design trade-offs and avoid unnecessary design revisions by performing functional validation on designs prior to layout or manufacturing.

Supplier Links/Search

Search online supplier databases and link or embed parametric data to your design components to match real-time device parameters, pricing, and availability, putting the most up-to-date information at your fingertips throughout the entire design process to make immediate decisions to meet electrical requirements, budget, and deadlines.

Version Control

Manage and compare all history and changes made to design files directly and gain greater control over changes made to your design knowing exactly what changes were made and by whom.

Component Parametric Database Support

SOLIDWORKS File Support

Be confident in knowing the exact intent of your mechanical designer with SOLIDWORKS 3D file support that provides the most precise and pure version of component models and enclosures, ensuring that your 3D clearance check process provides a clear picture on board fit.

Design Commenting and Revision Management

Take complete control of your design process and understanding exactly what changes were made to your board design and when. Detailed design revision comments allow you to see a clear change history with the ability to accept or reject the changes.